If you spend any time talking with uniform manufacturers, the conversation almost always circles back to the same question. Not fabric. Not freight. Not forecasts. People.

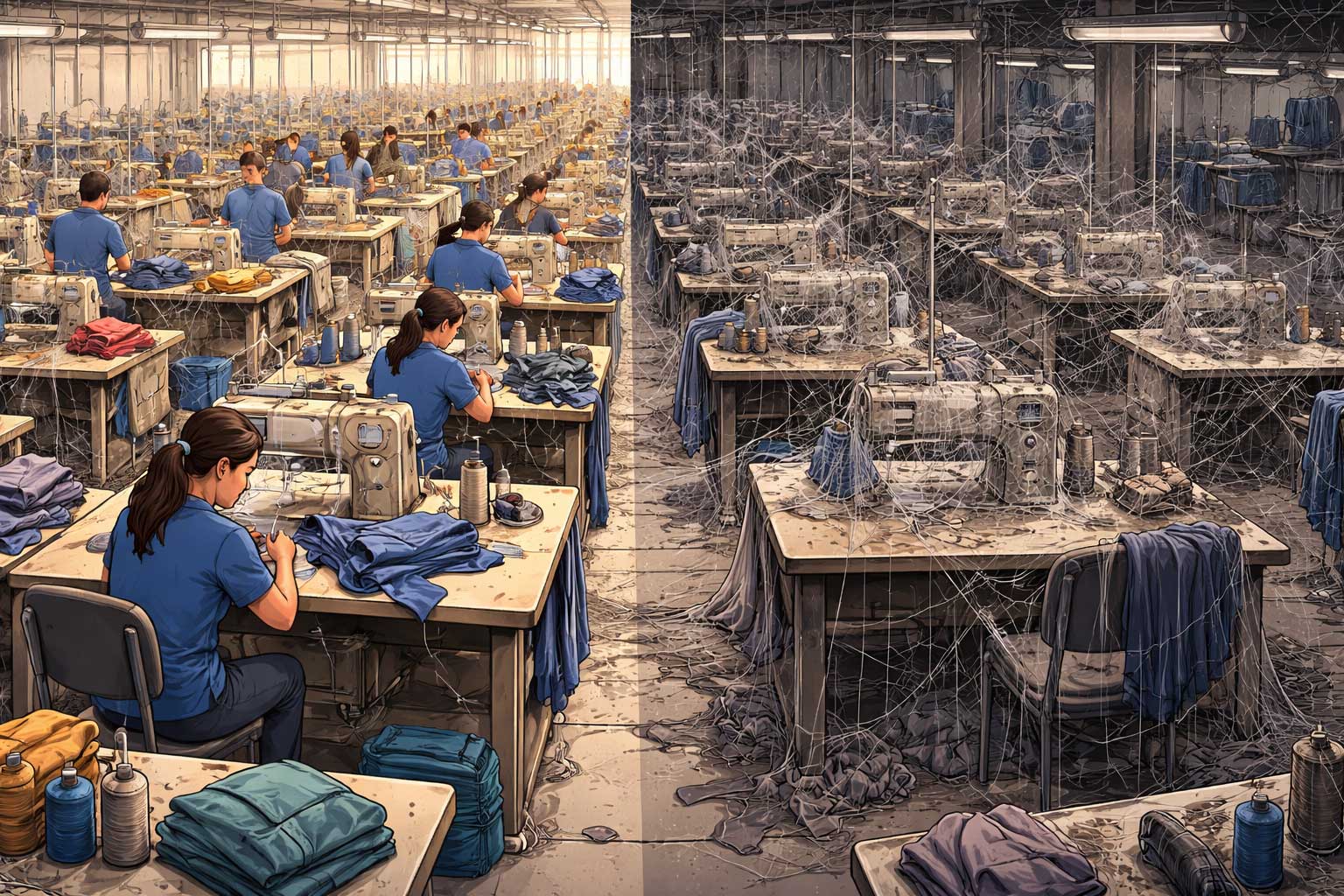

The challenge is not that demand has vanished. In many segments, demand remains steady or is growing. The challenge is who will design, cut, sew, finish, manage, inspect, and ship the products that keep public safety professionals, healthcare workers, and service teams protected and visible.

The numbers behind this challenge are sobering. By some estimates, the United States manufacturing sector will need to fill as many as 3.8 million jobs by 2033. Most of those openings are driven by retirements rather than growth. Nearly half of those roles could remain unfilled if workforce trends do not change.

This is not a future problem. It is already happening. Throughout 2025, US manufacturers consistently reported more than 400,000 open positions that they were unable to fill. These were not seasonal jobs or speculative postings. They were ongoing roles needed to keep operations running. Vacancy rates in manufacturing have hovered around 4 to 5 percent nationally, with some subsectors experiencing even higher gaps.

One of the drivers is simple math. About 26 percent of the current manufacturing workforce is age 55 or older. Retirement is not a theory. It is a calendar event. At the same time, younger workers are not lining up to replace them. Surveys show that only about 14 percent of Gen Z respondents say they would even consider a manufacturing career.

That 14 percent number is not a vacancy rate. It is a perception indicator. It tells us how the next generation views the industry before they ever walk through a plant door.

For uniform and workwear manufacturers, this matters more than most industries. Domestic production is often tied to speed, compliance, customization, and quality control. Many companies want more domestic capacity, not less. But domestic capacity requires people. When people are scarce, every inefficiency gets louder.

This is where strategy needs to evolve.

Automation and technology are no longer optional upgrades. They are workforce multipliers. Advanced cutting systems, automated sewing equipment, robotics, digital pattern development, and smarter warehouse workflows allow fewer people to do more work safely and consistently. In many cases, technology is not replacing workers. It is protecting them, extending their careers, and making the jobs that remain more skilled and more interesting.

Efficiency also needs to be reconsidered as a design issue. How garments are engineered, how trims are attached, how size ranges are structured, and how customization is managed all affect labor intensity. The companies that win will be the ones that simplify intelligently without sacrificing performance, compliance, or comfort.

There is also a cultural and storytelling challenge that the industry cannot ignore. Uniform and workwear manufacturing still fights outdated stereotypes. Many young workers imagine factory jobs as repetitive, isolated, and disconnected from purpose. That image does not match reality, especially in the uniform sector.

This industry solves real problems. Firefighters depend on protective gear that performs under extreme conditions. Healthcare workers rely on garments that protect them and their patients. Public safety professionals wear uniforms that improve visibility, mobility, and safety in unpredictable environments. Sustainability initiatives reduce waste, chemical exposure, and environmental impact. These are not abstract benefits. They are tangible outcomes.

Younger workers consistently say they want meaning, impact, and alignment with their values. Uniform and workwear manufacturing checks those boxes. The challenge is making that connection visible. Career pathways need to be explained clearly. The link between a job on the production floor and the person wearing the uniform in the field needs to be explicit.

Programs that introduce students and early career workers to the uniform and workwear industry in the right context matter more than ever. Apprenticeships, technical school partnerships, internships, and industry supported education programs help reframe manufacturing as problem solving, not just production.

The workforce challenge is not going away. The data makes that clear. But neither is demand for the products this industry creates. The companies that thrive will be the ones that combine automation, technology, smarter design, and better storytelling. Staffing the domestic workforce will remain difficult, but it is a challenge that can be managed with intention.

Finding talent matters as much as finding fabric. In many ways, it matters more.

⸻

Sources

Fortune

https://fortune.com/2025/12/04/gen-z-4-million-new-manufacturing-jobs-america-boomer-retire-one-trade-job-young-people-dont-want/

CargoSon

https://www.cargoson.com/en/blog/how-many-manufacturing-jobs-are-unfilled-in-the-us

The Manufacturer

https://www.themanufacturer.com/articles/study-warns-u-s-manufacturing-could-face-3-8-million-job-openings/

AMTEC

The State of the U.S. Manufacturing Workforce (2025–2026 Benchmark Report)

Apollo Technical

https://www.apollotechnical.com/manufacturing-statistics-in-the-us/