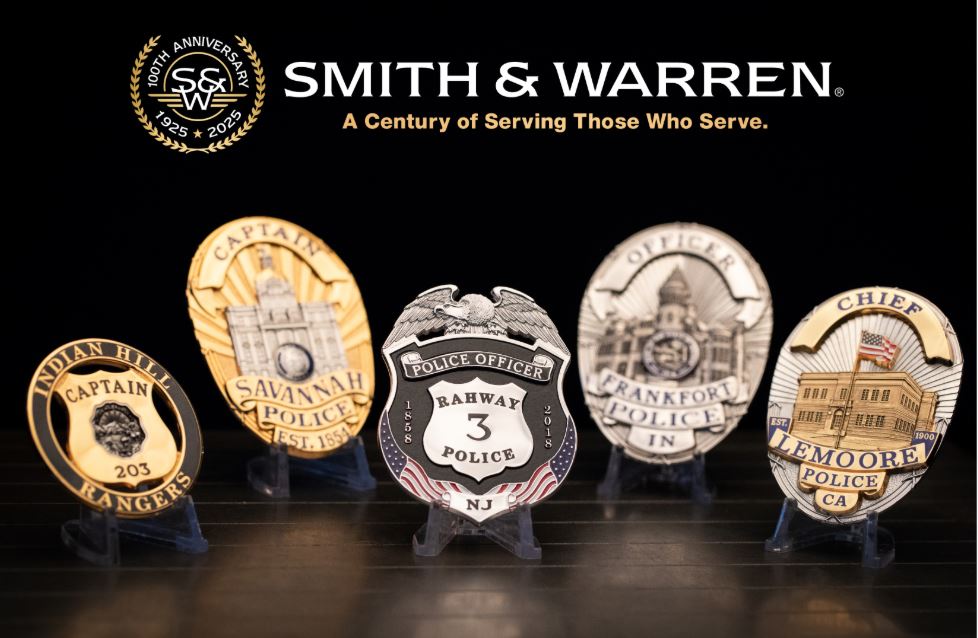

Smith & Warren celebrates its 100th anniversary this year — a rare milestone in American manufacturing and a reflection of the company’s deep commitment to craftsmanship, service, and tradition. Since 1990, under the leadership of the Galperin family, the company has grown from a small regional badge maker into a national leader, serving thousands of law enforcement, fire, EMS, corrections, and security agencies across the U.S. and abroad.

When Lee Galperin, president of Smith & Warren, joined the company in 2000, he quickly made an impact in sales and recognized just how much opportunity was out there. But it became clear that in order to grow the right way, the company needed more than ambition — it needed a solid foundation. “We were saying yes to opportunities that pushed the limits of what we could do — whether it was an order size we weren’t used to or a skill we hadn’t fully developed,” Galperin recalls. “I realized we couldn’t grow at scale without first building our capabilities, and that meant embracing technology in every part of the business — not just manufacturing, but design, operations, communication, and customer service. We needed a blueprint for success, and technology was a critical part of that.”

Those early days became teachable moments. The company strengthened its foundation and set realistic goals, realizing that sustainable growth doesn’t just mean doing more — it means doing better, every single time.

Their ability to evolve, their investments in technologies and an uncompromising commitment to craftsmanship is at the center of their longevity.

“One of the biggest challenges was modernizing the business without losing what made it special — the craftsmanship, the personal relationships, the deep respect for tradition,” Galperin recalls of those early years. “We had to upgrade systems, add new processes, and expand our team, all while continuing to deliver the same product quality and service our customers relied on.”

Customers’ wants have not changed over time. They want a product to wear with pride; a badge that reflects their identity, their department, and their commitment to service.

What has changed is the level of expectation around quality, design, and turnaround time. “Today’s public safety professionals want a badge that not only meets functional needs but also looks exceptional — it needs to be precise, durable, and carry the right symbolism and detail,” he noted.

Customization, too, is more important. Agencies want to differentiate themselves, to tell their story through their badge. Smith & Warren leans into this by offering more design options and working closely with departments to create truly unique pieces.

Craftsmanship heart of business

Smith & Warren is always on the hunt for new tools and technologies that can improve the way they operate, but craftsmanship is at the heart of what they do. The company uses advanced 3D modeling and laser die-making technology to bring precision and consistency to even the most complex designs. But the creative vision and the understanding of what makes a badge feel right comes from staff. And AI is used to analyze operational data, improve forecasting, and streamline certain internal workflows.

But don’t expect AI to take over the design process. “Our badge designs are deeply personal to the departments we serve, so we don’t rely on AI to generate creative work. That process still starts and ends with human designers working closely with our customers,” Galperin said. “What AI can do is help behind the scenes — organizing reference materials, accelerating file handling, or automating repetitive tasks so our designers can focus more on the creative part of their work”

American made products more important than ever

American manufacturing isn’t always the easiest or cheapest path, but it’s the only way forward for Smith & Warren. As more departments ask about American manufacturing and sustainability, the company believes its U.S. commitment resonates with customers now more than ever.

“It absolutely gives us an edge, not just because we can respond faster or maintain tighter quality control, but because our customers know we’re fully invested in the work,” Galperin said. “We’re not outsourcing craftsmanship or cutting corners. We’re creating jobs, building skills, and reinvesting in our people and our community.”

It’s that commitment that allows Smith & Warren to focus on long-term success over short-term gains. The company is a family-owned business, which gives it the independence to make decisions that reflect their values and priorities, and not just what looks good on a quarterly report. “Going public would risk compromising that culture, and it’s simply not the path for us,” Galerin said.

Managing Economic Uncertainty

There’s always a level of concern when economic uncertainty or budget constraints come into play, especially in industries like public safety. Smith & Warren is built to be resilient, preparing for downturns by staying disciplined, managing resources carefully, and continually reinvesting in the things that matter most: people, processes, and products.

In difficult times, departments may delay purchases or stretch budgets, but the need for high-quality badges doesn’t go away. “We offer flexibility when we can and help departments find solutions that work within their constraints”, noted Galperin.

Building a legacy

Focused on building a legacy, Smith & Warren sees the coming decades as an opportunity to strengthen relationships with public safety agencies and the network of dealers that distribute its products. Above all, it will continue its commitment to craftsmanship and American badge making with the care and integrity it deserves.

Galperin is also hitting a milestone this year. “I turn 50, and I feel like I’m just getting started. There’s still so much to do,”